Among the many pieces of equipment in industrial settings, dual-mode screw inverter chillers shine like unique gems, offering exceptional value. For businesses, understanding their special features not only maximizes their efficiency but also brings unexpected benefits in cost control and productivity improvement. Whether in the production workshops of large factories or the server rooms of data centers, dual-mode screw inverter chillers play a vital role. Today, let’s explore what makes them so special.

1. Dual-Mode Operation

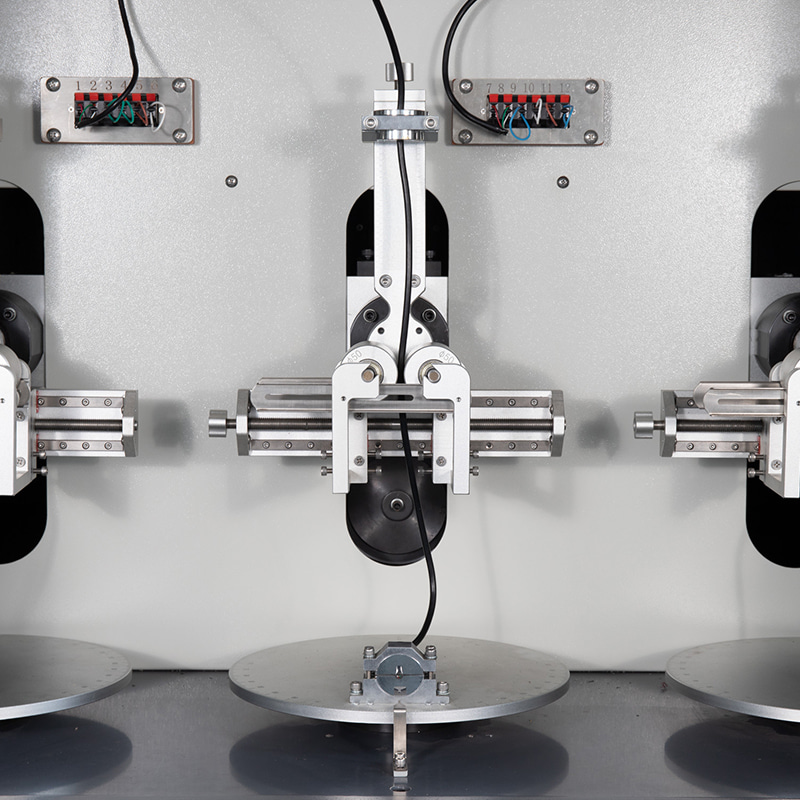

One of the standout features of dual-mode screw inverter chillers is their ability to operate in two distinct modes: cooling and ice-making. They can seamlessly switch between these modes based on actual needs. In cooling mode, they provide a stable low-temperature environment for production equipment and office spaces, effectively reducing temperatures and ensuring smooth operations while preventing overheating-related failures or reduced lifespan. In ice-making mode, they meet the demands of specialized processes, such as rapid ice production in food processing or ice storage for cooling in buildings during off-peak hours, releasing stored cooling during peak hours to save on electricity costs.2. Advantages of Screw Inverter Technology

Another key feature is the use of screw inverter technology. Screw compressors are known for their compact structure and high efficiency, and the addition of inverter functionality takes their performance to the next level. The chiller can automatically adjust the compressor speed based on actual cooling load demands, eliminating the frequent start-stop issues of traditional fixed-speed chillers. During low-load operation, the inverter chiller reduces energy consumption and minimizes waste. For businesses, this translates to significant long-term cost savings and aligns with modern sustainability goals by reducing energy consumption and emissions.

3. Precise Temperature Control

Dual-mode screw inverter chillers excel in temperature control, maintaining precise temperatures within a narrow range. This is crucial for industries with stringent temperature requirements, such as electronic chip manufacturing or precision instrument processing. Accurate temperature control ensures consistent product quality, reduces defect rates caused by temperature fluctuations, and enhances overall production efficiency.4. Wide Applicability

These chillers are highly versatile, suitable for both small and large enterprises across industrial and commercial sectors. In industrial applications, they are used for temperature regulation in industries like chemicals, pharmaceuticals, and textiles. In commercial settings, they provide cooling for air conditioning systems in malls, hotels, and other spaces, meeting diverse cooling needs across different areas and time periods.With their dual-mode operation, screw inverter technology, precise temperature control, and wide applicability, dual-mode screw inverter chillers hold an irreplaceable position in industrial and commercial settings. They act as reliable assistants, safeguarding production and operations while improving efficiency, reducing costs, and ensuring product quality. When considering cooling equipment, dual-mode screw inverter chillers are undoubtedly a top-tier choice worth exploring.