Choosing the right tile cutter can dramatically impact the success of your projects—especially in Southeast Asia, where tile types, job scopes, and environmental conditions vary greatly. Whether you're a contractor, a distributor, or a retailer, understanding what machine fits your local market can help reduce waste, boost productivity, and increase client satisfaction.

Here’s a step-by-step guide to making the right choice.

📐 1. Understand the Tiles You Cut Most Often

Different regions have different preferences. For example:

-

Indonesia and Malaysia use a lot of porcelain and granite in modern housing.

-

Thailand and the Philippines often require ceramic or patterned tiles for decorative use.

-

Vietnam increasingly favors large-format tiles for commercial projects.

✅ What to Choose:

A machine compatible with the hardest materials you commonly cut. Look for models with:

-

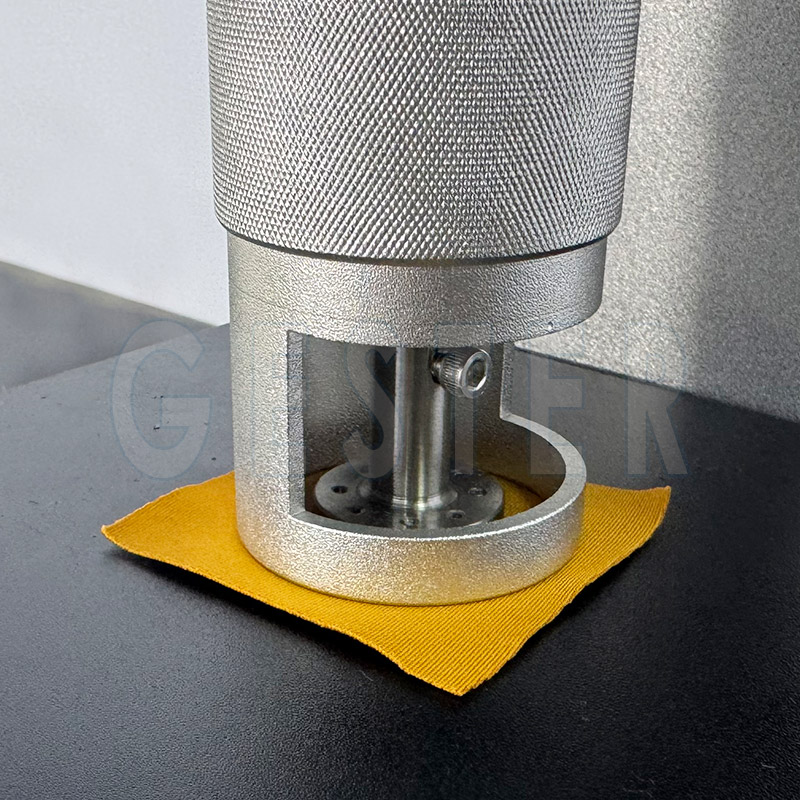

Water-cooled diamond blades

-

High cutting torque

-

Extended rail length for large tiles

🔗 See Wandeli cutters built for tough tiles

🛠️ 2. Match Cutter Size to Typical Tile Size

Large tiles (600mm–1800mm) are common in SEA commercial builds. Using a cutter that's too short can crack tiles or result in imprecise cuts.

✅ What to Choose:

Select a model that exceeds your largest common tile length. Popular options include:

-

QX-ZD-1200 for 1200mm tiles

-

QXZ-ZD-1800 for extra-large tiles

🔗 Explore cutting tools for large-format tiles

🌡️ 3. Consider Environmental Conditions

SEA’s tropical humidity impacts machine performance. Basic manual cutters may wear out faster or overheat.

✅ What to Choose:

Electric tile cutters with built-in water cooling, anti-corrosion materials, and sealed motor compartments. Wandeli models are built with these tropical-use requirements in mind.

🔗 Why contractors in SEA prefer Wandeli

👷 4. Determine Your Usage Frequency

High-volume contractors or tile suppliers need machines that can cut all day without overheating. Occasional installers may prefer a more portable model.

✅ What to Choose:

-

For daily commercial use: QX-ZD-1200 or QX-ZD-1800

-

For on-the-go installations: Lightweight and foldable models

🔗 Contact us for usage-based machine recommendations

💰 5. Balance Cost with Long-Term ROI

Cheaper machines often mean higher tile waste, more breakdowns, and less precision.

✅ What to Choose:

Go for a reliable brand like Wandeli, known for:

-

Durable components

-

Consistent performance

-

Long-term savings

🔗 See how Wandeli improves ROI

🧩 Final Thoughts

Choosing the right tile cutter isn’t just about price—it’s about performance, reliability, and fit for your local market. By matching the machine to your tile type, usage frequency, and project scale, you’ll get better results and grow your reputation.

🔗 Compare all Wandeli models and specs

🔗 Contact Wandeli for local dealer info in SEA