When planning a tile installation project, one of the most common questions professionals and DIYers ask is: "Which is better – porcelain or ceramic tile?" Both materials are popular in flooring and wall applications, but they have distinct differences in terms of durability, appearance, cost, and how they perform when used with electric tile cutting machines.

In this article, we’ll break down the key differences and help you decide which tile type is best for your next project.

1. Material Composition & Durability

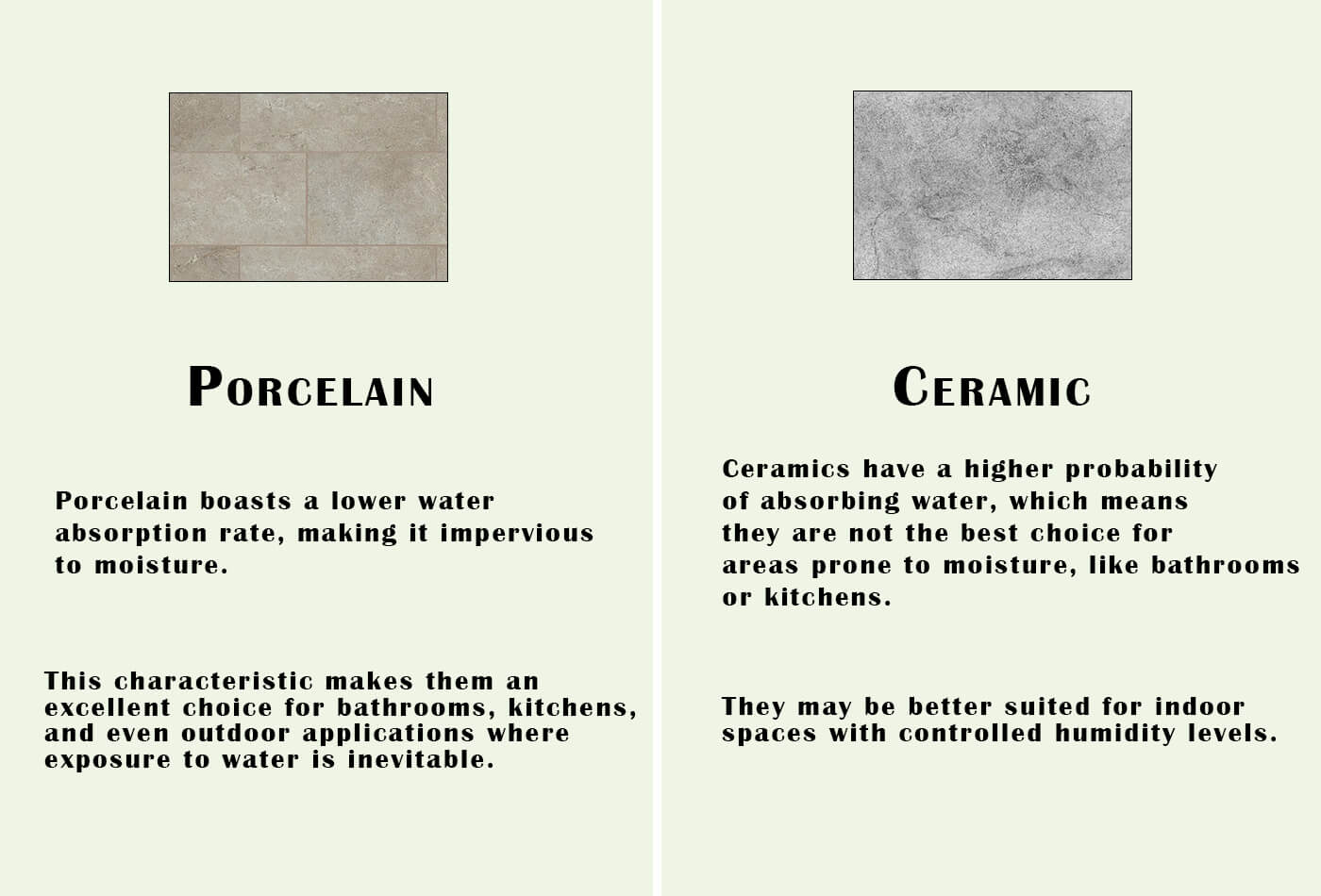

Porcelain tiles are made from finer, denser clay and fired at a higher temperature than ceramic tiles. This process makes porcelain harder, more durable, and more water-resistant, which is ideal for high-traffic areas, outdoor use, and wet environments like bathrooms and kitchens.

Ceramic tiles, while still strong and versatile, are slightly more porous and less dense, making them better suited for interior walls and light-use floors.

Tip: Due to its density, porcelain is tougher to cut. Using a professional electric tile cutting machine with a water-cooled blade ensures a clean, chip-free finish.

2. Appearance & Design Options

Ceramic tiles often come in a wider variety of colors, textures, and decorative patterns, thanks to the ease of applying glazes. Porcelain tiles are usually available in more neutral and natural stone-look finishes, offering a more sophisticated and modern aesthetic.

Both types can be precisely shaped using electric tile cutters, but porcelain may require a more powerful model with a brushless motor to handle the harder material effectively.

3. Cost Considerations

Generally, ceramic tiles are more affordable than porcelain, both in terms of material and installation costs. If you’re working within a budget and your project is for low-traffic, indoor areas, ceramic may be the better choice.

However, if you’re looking for long-term durability and water resistance, especially for floors or outdoor applications, porcelain may justify the higher price tag.

4. Ease of Cutting & Installation

Ceramic tiles are easier to cut and drill, making them a favorite for DIY installers. A standard electric tile cutter or manual tile cutting machine can handle ceramic without much resistance.

Porcelain, being harder and denser, requires a high-powered electric tile cutting machine, preferably with water-cooling and laser guidance to ensure precise, clean cuts without cracking the surface.

Tip: Investing in a quality automatic electric tile cutting machine is key when working with porcelain to reduce breakage and speed up installation.

5. Which Should You Choose?

-

Choose Porcelain if you need a tile that’s highly durable, water-resistant, and suitable for heavy-use or outdoor areas.

-

Choose Ceramic if you want an affordable, stylish option for indoor walls or low-traffic floors, and if ease of cutting is important.

Final Thoughts

The right tile depends on your project’s specific needs. No matter which you choose, using the right electric tile cutting machine will make a big difference in the speed, safety, and precision of your installation. For professional results, especially with porcelain, opt for a wet-cut electric tile saw with a powerful motor and stable guide rails.

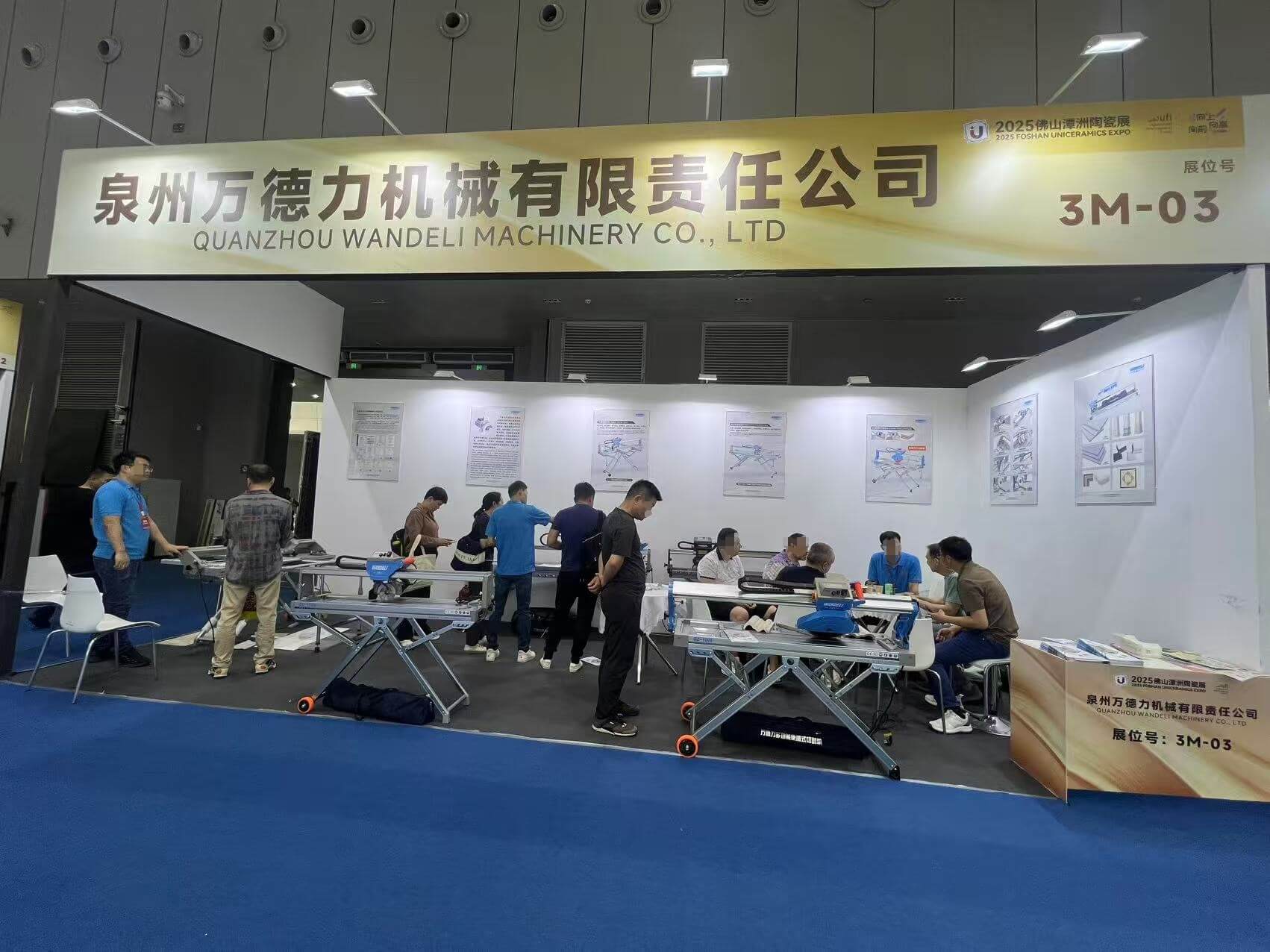

Why Choose Wandeli's 4500W Electric Tile Cutting Machine for Porcelain and Ceramic Tile Projects?

When working with hard materials like porcelain or large-format ceramic tiles, precision and power are everything. As discussed in our earlier article comparing porcelain and ceramic tiles, porcelain is denser and more durable — but also more challenging to cut. That’s where the Wandeli Electric Tile Cutting Machine with its powerful 4500W brushless motor makes all the difference.

Whether you're a professional tile installer, contractor, or renovation specialist, this high-performance machine is designed to give you clean, accurate cuts every time — even through the toughest porcelain panels.

Built for Power and Performance

The 4500W brushless motor featured in Wandeli’s advanced electric tile cutting machine provides unmatched cutting strength and consistency. Brushless technology not only delivers more torque and efficiency, but it also results in lower maintenance, longer motor life, and quieter operation.

This level of power is essential when cutting dense porcelain tiles, porcelain slabs, or ceramic boards — especially when precision edges are required for tight installations or luxury finishes.

Clean Cuts with Wet-Cutting Technology

Dust control and blade cooling are crucial when working with tile. Wandeli’s machines are equipped with a wet-cutting system, using water to suppress dust and reduce friction on the blade. This not only keeps the workspace cleaner and safer but also extends the blade’s lifespan — an essential feature for long-term use in professional environments.

Many models also include integrated water recycling systems, enhancing environmental efficiency and reducing water waste on the job site.

Ideal for Porcelain, Ceramic, and Large-Format Panels

Unlike many standard cutters that struggle with oversized or ultra-hard materials, Wandeli’s 4500W brushless motor tile cutter is designed specifically for the most demanding applications. It handles:

-

Porcelain panels and slabs

-

Ceramic floor and wall tiles

-

Vitrified tiles

-

Marble and stone-look tiles

Combined with a laser guide and adjustable cutting depth, this machine ensures ultra-precise results on every cut.

Professional Efficiency and Easy Operation

Wandeli cutting machines are known for their intuitive controls, stable rails, and smooth operation — ideal for professionals who value both speed and precision. The 4500W unit offers effortless, high-speed cutting without compromising accuracy.

With fast setup times, low blade vibration, and a rigid frame structure, Wandeli machines are a smart investment for any tile business looking to increase output and quality.

Why Professionals Prefer Wandeli

For serious tile work, especially when cutting porcelain, professionals trust the Wandeli electric tile cutter for its:

-

4500W brushless motor power

-

Clean and accurate wet cuts

-

Durability and minimal maintenance

-

Compatibility with a wide range of tile materials

-

User-friendly and portable design

Whether you're working on a home remodel, a commercial build, or custom tile installations, Wandeli delivers consistent performance that meets the highest standards in tile cutting.

Conclusion

If you're searching for a powerful, precise, and reliable electric tile cutting machine, the Wandeli 4500W brushless model stands out as a top choice. With its unmatched cutting capability, efficient wet system, and professional-grade design, it's the ideal tool for tackling both porcelain and ceramic tile projects with confidence.