Ceramic cutting machine is divided into hand cutting machine, CNC cutting machine, multi-functional cutting machine and automatic cutting machine, equipment cutting after a period of time, you will find that the cutting accuracy is reduced, there is a breakdown of porcelain, off the reason, it may be cutting saw blade blunt or crack, then you need to replace the cutting saw blade of the cutting machine, What should we pay attention to when replacing the saw blade?

1200mm brushless automatic cutting machine

Tile cutting machine cutting saw blade replacement precautions:

1, before use, be sure to carefully read the manual of the cutting machine and the instructions on the packaging shell.

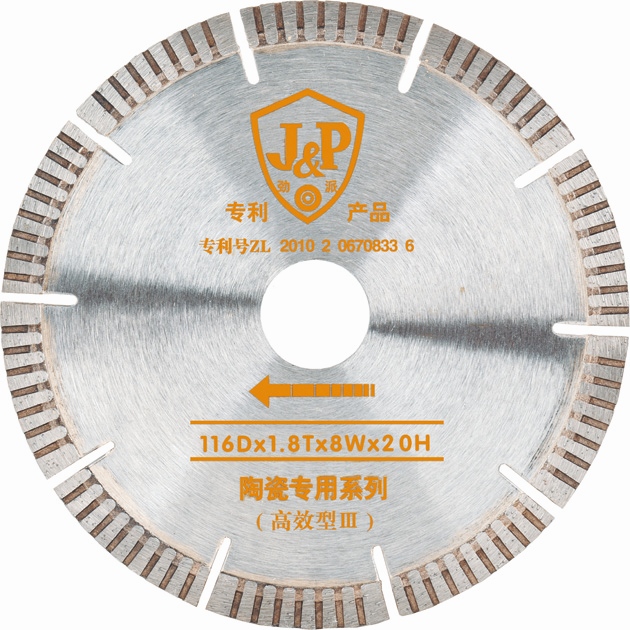

2. Select the type of saw blade according to the laser cutting material, and check whether the saw blade has gaps, misinterpretation, teeth loss, if the saw blade is damaged, do not use.

3, as far as possible to install the cutting machine saw blade shell protective cover, and wear a mask or safety protection eyes.

4, before the saw blade installation, please check whether the spindle of the cutting machine is vibrating, the saw blade will be installed with flanges and nuts set tight, after the installation must be and the saw blade management center hole is not firmly fixed on the platform flange, there will be a sealing ring when the cushion trap is good after buying gently force to promote the saw blade to determine whether the rotation is axial force shaking.

5, the installation of alloy saw blade before use need to pre-turn for one minute, until the equipment into the working state can be laser cutting work.

6, when non-automatic laser cutting work, be sure to gently select the material of the saw blade in normal operation, prohibit the use of force and hard push. It is prohibited to suddenly stop the saw blade in the middle of the laser cutting, otherwise it will cause the serrated fall, the saw shape change, and it is easy to cause danger.

7, hear abnormal sound in use, see abnormal shaking or abnormal cross-section, please terminate the work and search for abnormal reasons, immediately replace the saw blade.

8, please wipe the anti-rust agent immediately after laser cutting to prevent the saw blade from rust due to long-term non-use.

9, please hang the saw blade vertically in the dry special tool rack, avoid wet and cold areas. Do not put the saw blade flat on the ground, otherwise it is easy to cause the saw blade deformation. Square wood saw blade do not immediately fold, must be spaced packaging, to prevent the impact of the serrated, should be handled carefully.

10, the saw blade is not sharp to grind the serrated, not immediately grinding is easy to destroy the original view Angle of the serrated, affecting the laser cutting precision, reduce the service life of the saw blade.